HPMC for construction

Another name is Hydroxypropyl methyl cellulose . also we can called hpmc cellulose ethers .

Appearance - white or whitish powder

Particle size - 98.5 % min through 100 mesh

The carbonization temperature - 280-300 Deg.C

The bulk density - 0.25-0.70g/cm3(Usually around 0.5g/cm3)

Real specific gravity - 1.26-1.31

Browning temperature - 190-200 Deg.C.

Surface tension (2% water solution) - 42-56 dyn/cm

Hydroxypropyl methyl cellulose (HPMC) is a highly pure cotton cellulose as raw material, under alkaline conditions by special etherification and preparation . the hpmc is white or whitish powder . Hydroxypropyl methyl cellulose has thickening ability , it also can salt resistance, low ash powder,pH stability, water retention, dimensional stability and excellent film forming, it also has the wide range of enzyme resistance, dispersion and adhesion.The hpmc cellulose ethers are the variety of nonionic cellulose mixed ethers . It is a semi-synthetic , inactive, viscoelastic polymer that is widely used in ophthalmology as a lubricant and as an excipient & excipient in oral medications , it is found in a wide variety of commodities. As a food additive, hpmc cellulose can assume the following roles: emulsifiers, thickeners, suspending agents, and animal gelatin substitutes.The hpmc cellulose ethers chemical powders are widly used in construction materials , such as used for wall putty, tile adhesive, cement mortar, dry mix mortar, wall plaster, skim coat, mortar, concrete admixtures, cement, gypsum plaster, joints fillers, crack filler, etc.

The Performance:

1. Strong plasticity: apply to gypsum without adding starch ether, bentonite, magnesium silicate, etc., improve the workability of mortar, adjust viscosity, apply to no effort, no stick knife, strong plasticity

2. This product has high cost performance: few additives, obvious effect, convenient construction;

3. Convenient construction: improved the batch scraping system of gypsum, saving energy for workers, smooth and consistent hand, non-stick knife, improved the construction area of workers, and improved the construction efficiency.

4. Gypsum strength does not decrease: it is recommended to use a reasonable range and formula, and the strength of gypsum body does not decrease

The Application:

A. The cement mortar: The hpmc cellulose can improve dispersion of cement-sand and improve the plasticity and water retention of the mortar,it also can effect on preventing cracks and improve the strength of the cements.

B. The tile adhesives: The hpmc cellulose can improve the plasticity , it can improve the water retention of the pressed tile mortar and enhance the adhesive strength of the cement tiles and prevent powdering .

C. The Gypsum setting mud : The hpmc cellulose can improves water retention and processability, it also can improves the conglutination to the substrate.

D. The seam cement: it can added to the joint cement for gypsum board to improve fluidity & water retention.

E. The coatings: as a plasticizer for latex coatings, it has an effect on improving the handling properties and fluidity of coatings and putty powder.

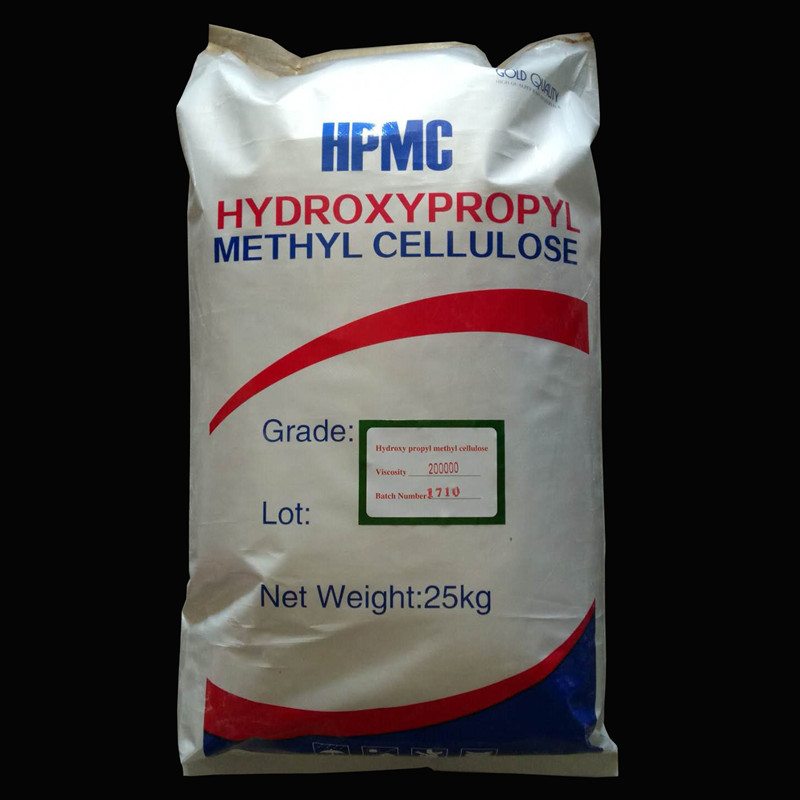

The HPMC cellulose package conditions :

Packing: usually it is 25kg plastic bags

Quantity/20GP: 12MT with pallets and 14MT without pallets

Quantity/40GP: 24MT with pallets and 28MT without pallets