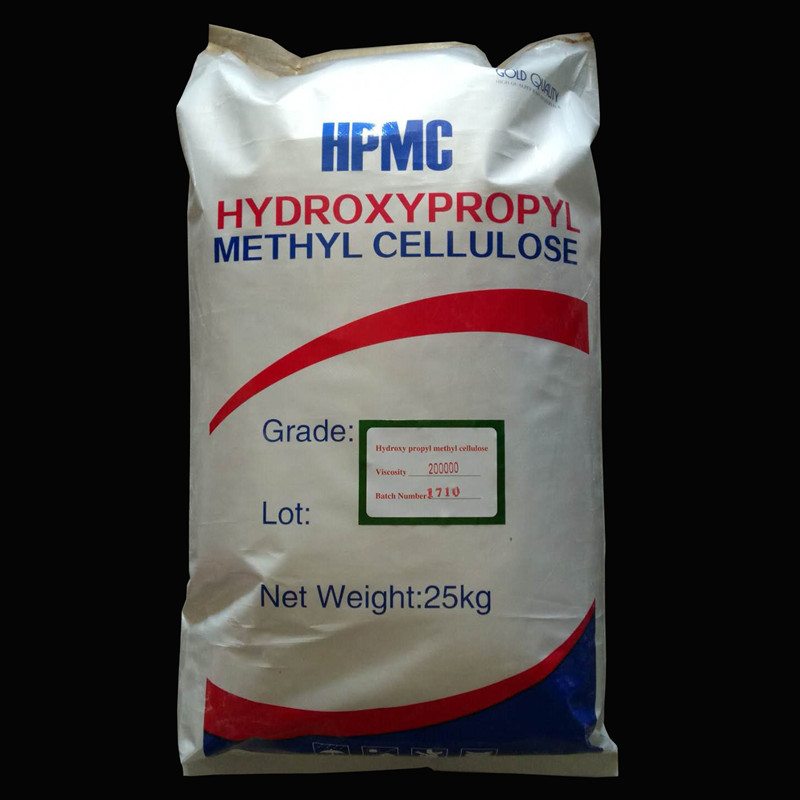

Mecellose hpmc cellulose ether

China mecellose hpmc cellulose ether for gypsum adhesive

High viscosity low price 200000 cps mecellose hpmc cellulose ether

Hydroxypropyl methylcellulose (INN name: Hypromellose), also simplified as hydroxypropyl methylcellulose (HPMC), is a variety of nonionic cellulose mixed ethers. It is a semi-synthetic, inactive, viscoelastic polymer .Hydroxypropyl Methyl Cellulose (HPMC) is also named as MHPC, are types of non-ionic cellulose ether, which are a powder of white to off-white color, that function as a thickener, binder, film-former, surfactant, protective colloid, lubricant, emulsifier, and suspension and water retention aid. In addition, these types of cellulose ethers exhibit properties of thermal gelation, metabolic inertness, enzyme resistance, low odor and taste, and pH stability. HPMC are widely used in construction,pharmaceutical,food,cosmetic,detergent,paints,textiles etc.We can provide the general grade HPMC, we also designed the modified HPMC according to customer requirements. After modified, we can get the product which have long open time, good anti-sagging,good workability etc.

Performance and application areas:

1. Strong plasticity: applied to gypsum without adding starch ether, bentonite, magnesium aluminum silicate, etc., improve mortar workability, adjust viscosity, apply effortless, non-stick knife, strong plasticity

2. The product has a high cost performance: low admixture, obvious effect, easy to construct;

3. Convenient construction: improve the batch scraping of gypsum, workers to save energy, feel smooth and coherent, non-sticky knife, improve the construction area of workers, improve construction efficiency.

4. Does not reduce the strength of gypsum: Use within a reasonable range of recommendations with a reasonable formula, do not reduce the strength of plaster gypsum body

Exterior: White or off-white powder

particle size: the passing rate of 80 mesh is 100% the passing rate of 100 mesh is more than 99.5%

Charring density:280-300℃

Apparent density: 0. 25-0.70g/cm(usually around 0.5g/cm), the proportion is 1.26-1.31

Thermochromic temperature: 190-200℃

Surface tension: 2% of aqueous solution is 42-56dyn/cn.

Applications

Wall putty

•Water retention: maximized water content in slurry.

•Anti-sagging: when spreading a thicker coat corrugation can be avoided.

•Increased mortar yield: depending on the weight of the dry mixture and appropriate formulation ,HPMC can increase the mortar volume.

Exterior Insulation and Finish System ( EIFS )

•Improved adhesion.

•Good wetting ability for EPS board and substrate.

•Reduced air entrancement and water uptake.

Self-leveling

•Protection from water exudation and material sedimentation.

•No effect on slurry fluidity with low viscosity

HPMC, while its water retention characteristics improve the finish performance on the surface.

Crack Filler

·Better workability: proper thickness and plasticity.

·Water retention ensures prolonged work time.

·Sag resistance: improved mortar bonding ability.

Tile Adhesives

•Better workability: lubricity and plasticity of plaster is ensured, mortar can be applied easier and quicker.

•Good water retention: prolonged opening time will make tiling more efficient.

•Improved adhesion and sliding resistance: especially for heavy tiles.

Dry mix mortar

•Easy dry mix formula due to cold water solubility: lump formation can be easily avoided, ideal for heavy tiles.

•Good water retention: prevention of fluid loss to the substrates, the appropriate water content is kept in mixture which guarantees longer concreting time.

Cement Plaster

•Increased water demand: increased open time, expanded spry area and more economical formulation.

•Easier spreading and improved sagging resistance due to improved consistency.