Putty powder FAQ - hydroxypropyl methyl cellulose

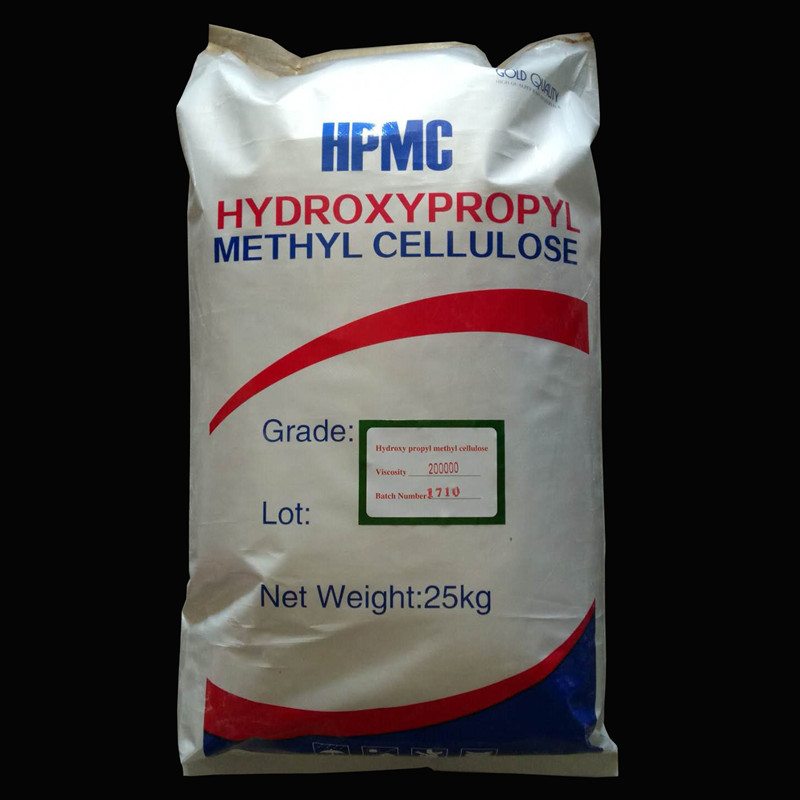

1. What are the main technical indicators of hydroxypropyl methyl cellulose (HPMC)?

Hydroxypropyl content and viscosity, which most users care about.High hydroxypropyl content and generally better water retention.High viscosity, water retention, relatively (but not absolutely) good, high viscosity, good for cement mortar.

2. What is the main role of HPMC in the application of putty powder?

HPMC putty powder, its thickening, water and construction of three functions.

Thickening: cellulose can be thickened and suspended to keep the solution uniform and prevent hanging.Water retention: putty powder drying slowly, auxiliary calcium calcium reaction under the action of water.Structure: cellulose can lubricate putty powder with good structure.

3. Powder putty powder has no relationship with HPMC?

The discharge of putty powder was mainly related to the quality of grey calcium, and had little relationship with HPMC.Calcium content and CaO, Ca (OH) 2 in the calcium ash in an inappropriate proportion will lead to powder fall.If it is related to HPMC, the poor water retention of HPMC will also lead to powder loss.4. What is the content of hydroxypropyl methyl cellulose (HPMC) in putty powder?

The amount of HPMC cellulose used in practical applications depends on the climate, temperature, local calcium ash quality, putty powder formulation and "customer required quality".Generally speaking, between four and five kilos.For example: Beijing putty powder, mostly put 5 kg;Guizhou is mostly 5 kg in summer and 4.5 kg in winter.Yunnan is very small, usually 3 to 4 kilograms and so on.

5. What is the viscosity of hydroxypropyl methyl cellulose (HPMC)?

General putty powder 100,000 can, and mortar requirements are higher, to 150,000 with.Moreover, the most important function of HPMC is to retain water and thicken it.In putty powder, as long as the water retention is good, the viscosity is low (7-80,000), of course, the viscosity may be larger, the better the water retention, when the viscosity is more than 100,000, viscosity has no effect on water retention.Big.

6, different USES, how to choose the right hydroxypropyl methyl cellulose (HPMC)?

Putty powder application: low requirements, viscosity of 100 thousand, can, maintain good water quality is very important.Mortar application: high requirements, high viscosity requirements, 150,000 better, the application of glue: instant product requirements, high viscosity.

7. What is the reason for the application of HPMC putty powder in putty powder foam?

HPMC has three functions: thickening, water retention and application in putty powder.Don't participate in any reaction.Causes of bubbles:

(1) too much water.

(2) the bottom layer is not dry, and the top is easy to be scraped and blistered.