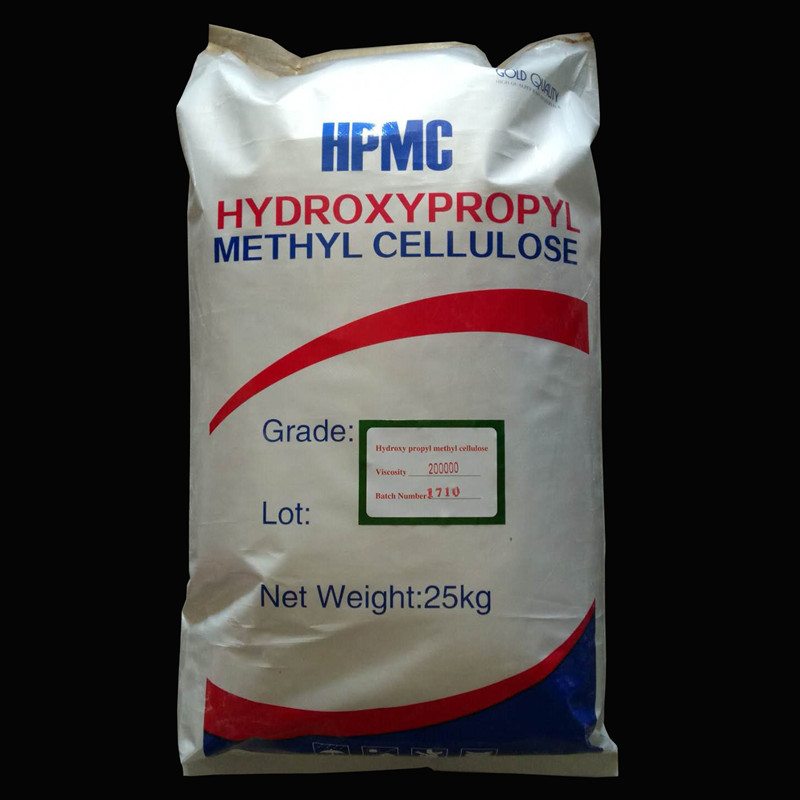

The role of hydroxypropyl methylcellulose (HPMC) in various building materials

1. The use of hydroxypropyl methylcellulose (HPMC) in building mortar plastering mortar

High water retention can make the cement fully hydrated, significantly increase the bond strength, and at the same time increase the tensile strength and shear strength, greatly improve the construction effect and improve work efficiency.

2. The role of hydroxypropyl methylcellulose (HPMC) in water-resistant putty powder

In the putty powder, the cellulose ether mainly protects water, bonds and lubricates, avoids cracking and dehydration caused by excessive water loss, enhances the adhesion of the putty, reduces the sag phenomenon during construction, and makes the construction smoother.

3. The role of hydroxypropyl methylcellulose (HPMC) in the plastering plaster series

In the gypsum series, the cellulose ether mainly plays the role of retaining water, increasing lubrication, and has a certain retarding effect. It solves the problem that the drum is opened and the initial strength is not reached during the construction process, and the working time can be prolonged.

4. The role of hydroxypropyl methylcellulose (HPMC) in the interface agent

Mainly used as a thickener to improve tensile strength and shear strength, improve surface coating, enhance adhesion and bond strength.

5. The role of hydroxypropyl methylcellulose (HPMC) in external thermal insulation mortar

In this material, cellulose ether focuses on bonding and increasing strength. It is easier for sand to coat, improve work efficiency, and has anti-flow effect. Higher water retention performance can prolong the working time of mortar and improve resistance. Shrinkage and crack resistance, improve surface quality and improve bond strength.

6. The role of hydroxypropyl methylcellulose (HPMC) in tile adhesives

The higher water retention capacity does not require pre-soaking or wetting the tiles and the base, and significantly improves the bonding strength. The slurry can be constructed in a long, delicate, uniform, convenient construction, and has good resistance to runtability.

7. The role of hydroxypropyl methylcellulose (HPMC) in caulking agents and furrowing agents

The addition of cellulose ether gives it good edge adhesion, low shrinkage and high abrasion resistance, protecting the base material from mechanical damage and avoiding the effects of penetration on the entire building.

8. Use of hydroxypropyl methylcellulose (HPMC) in DC flat materials

The stable adhesion of cellulose ether ensures good fluidity and self-leveling ability, and it controls the water retention rate to enable rapid solidification and reduce cracking and shrinkage.