hydroxypropyl methyl cellulose (hpmc) - detail introduction

What is HPMC?

Hydroxypropyl methylcellulose, also known as hypromellose, cellulose hydroxypropyl methyl ether, is obtained by using high purity cotton cellulose as a raw material and special etherification under alkaline conditions.

Hydroxypropyl methylcellulose, also known as hypromellose, cellulose hydroxypropyl methyl ether, is obtained by using high purity cotton cellulose as a raw material and special etherification under alkaline conditions.

HPMC cellulose is a non-ionic cellulose ether made from natural high polymer cellulose by a series of chemical processing. It's an odorless, tasteless and non-toxic white powder. Dissolving it in cold water will form a transparent and thick solution. it possesses many attributes such as thickening, binding, dispersing, emulsifying, film forming, suspending, absorbing, gelling, surface activity, water maintaining and protective colloid properties.

What is the HPMC' Physical and chemical properties?

1. Appearance: White or white powder, odorless, tasteless, non-toxic

2. Particle diameter fineness: 100 mesh pass rate greater than 98.5 %; 80 goal pass rate greater than 100 %

3. HPMC dissolves in cold water to form a transparent and viscous solution. Since it contains a certain amount of hydrophobic methoxy group, this product can be soluble in some organic solvents, and the best use range of aqueous solution viscosity is PH3.0-10 .0

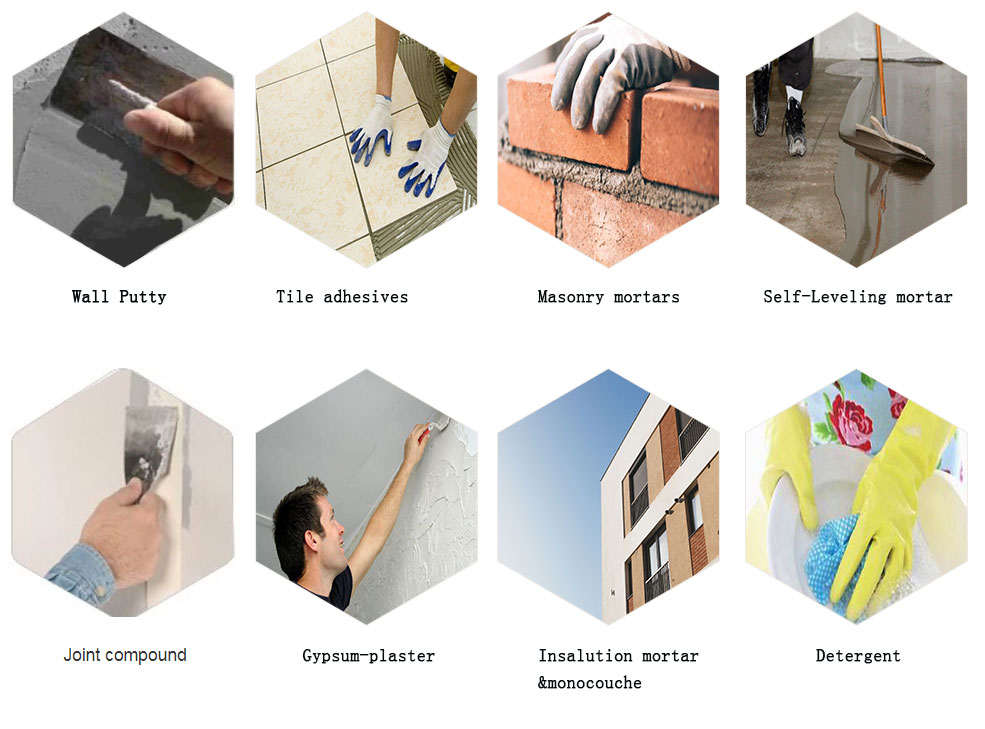

What is the HPMC'Performance and application?

1. Strong plasticity: applied to gypsum without adding starch ether, bentonite, magnesium aluminum silicate, etc., improve mortar workability, adjust viscosity, apply effortless, non-stick knife, strong plasticity

2. The product has a high cost performance: low admixture, obvious effect, easy to construct;

3. Convenient construction: improve the batch scraping of gypsum, workers to save energy, feel smooth and coherent, non-sticky knife, improve the construction area of workers, improve construction efficiency.

4. Does not reduce the strength of gypsum: Use within a reasonable range of recommendations with a reasonable formula, do not reduce the strength of plaster gypsum body

5.Enhances water retention--improved water retenion can protectcement and plaster against poor solidification and cracking due to speedy drying and inefficient mixing with water.

6.Workablilty--mortar plasticizing quality can be improved, which in turn will improved the workability of painting and working efficiency.

7.Binding--Due to increased plasticizing quality, mortar can be a better binde.

8.Slipping resistance--Due to the thickening action of Cellulose Ether,the slipping phenomena of mortar from substance to be bound can be prevented more efficiently.

Plasters, Renders, & Stucco:

Base plasters

Decorative Finish Plasters

Repair Plasters

Insulating Renders

Adhesives:

Tile Adhesives

EIFS Adhesives

Wallpaper Adhesives

Jointing & Filling Compounds:

Self-leveling compounds

EIFS leveling compounds

Wall leveling compounds

Grouts

Special Applications:

Underwater Concrete

Extruded Construction Elements