HPMC Company,HPMC Manufacture from china

CAS 9004-65-3 Hydroxypropyl Methyl Cellulose HPMC

Hydroxypropyl methylcellulose (INN name: Hypromellose), also simplified as hydroxypropyl methylcellulose (HPMC), is a variety of nonionic cellulose mixed ethers. It is a semi-synthetic, inactive, viscoelastic polymer .

Hydroxypropyl methylcellulose (HPMC) is a nonionic cellulose ether prepared by a series of chemical processing using natural polymer material cellulose as a raw material. Hydroxypropyl methylcellulose (HPMC) is an odorless, non-toxic white powder that dissolves in cold water to form a clear, viscous solution. It has the properties of thickening, bonding, dispersing, emulsifying, film forming, suspension, adsorption, gelation, surface activity, moisture retention and protective colloid.

It is also used as thickener, stabilizer, emulsifier, excipient, water retention agent, and film-forming agent etc.in producing petrochemicals, building materials, paint removers, agricultural chemicals, inks, textiles, ceramics, paper. cosmetics and other products.

Physicochemical Properties

1. Exterior: White or off-white powder

2. particle size: the passing rate of 80 mesh is 100% the passing rate of 100 mesh is more than 99.5%

3. Charring density:280-300℃

4. Apparent density: 0. 25-0.70g/cm(usually around 0.5g/cm), the proportion is 1.26-1.31

5. Thermochromic temperature: 190-200℃

6. Surface tension: 2% of aqueous solution is 42-56dyn/cn.

| Type | Specification | Range mpa.s |

| Low Viscosity | 25 | 20-30 |

| 50 | 40-60 | |

| 100 | 80-120 | |

| High Viscosity | 4000 | 3500-5600 |

| 12000 | 10000-14000 | |

| Extra High Viscosity | 20000 | 17000-22000 |

| 30000 | 27000-32000 | |

| 40000 | 37000-42000 | |

| 60000 | 58000-65000 | |

| 100000 | 4100-5600 | |

| 200000 |

Specifications:

|

Appearance |

White or off white powders |

|

Carbonized Temperature |

280-300ºC |

|

Dry Loss, WT% |

≤5 |

|

Methyl Content, WT% |

28.0-30.0 |

|

Hydroxypropyl Content, WT% |

4.0-12.0 |

|

Ph(1% solution, 25ºC) |

7.0±1.0 |

|

Gel Temperature ºC |

58-65 |

|

Fineness, mesh |

80-120 |

|

Viscosity (2% solution, 20ºC,mpa.s) |

400-200000 |

The Application:

A. The cement mortar: The hpmc cellulose can improve dispersion of cement-sand and improve the plasticity and water retention of the mortar,it also can effect on preventing cracks and improve the strength of the cements.

B. The tile adhesives: The hpmc cellulose can improve the plasticity , it can improve the water retention of the pressed tile mortar and enhance the adhesive strength of the cement tiles and prevent powdering .

C. The Gypsum setting mud : The hpmc cellulose can improves water retention and processability, it also can improves the conglutination to the substrate.

D. The seam cement: it can added to the joint cement for gypsum board to improve fluidity & water retention.

E. The coatings: as a plasticizer for latex coatings, it has an effect on improving the handling properties and fluidity of coatings and putty powder.

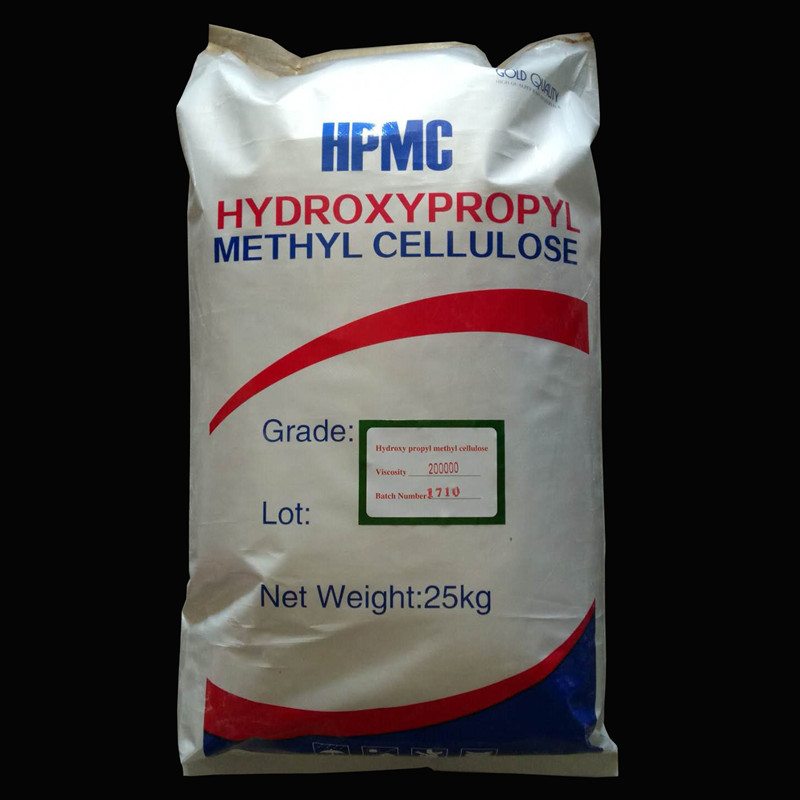

The HPMC cellulose package conditions :

Packing: usually it is 25kg plastic bags

Quantity/20GP: 12MT with pallets and 14MT without pallets

Quantity/40GP: 24MT with pallets and 28MT without pallets

we specialize in manfacture cellulose ethers for more than 10 years ,We have the five full set of advanced equipment ,our annual production capacity is 20000 tons of hpmc cellulose and 15000 tons of redispersible polymer powder per year ,today our products cover 30% of the domestic market , and we have established long term business relationship with many countries .

we specialize in manfacture cellulose ethers for more than 10 years ,We have the five full set of advanced equipment ,our annual production capacity is 20000 tons of hpmc cellulose and 15000 tons of redispersible polymer powder per year ,today our products cover 30% of the domestic market , and we have established long term business relationship with many countries .